Food production, medical, automotive and industrial systems frequently use leak testers. Some manufacturers test products and their components before they are released to consumers to ensure quality control. Read More…

We are AMETEK MOCON, and we are dedicated to delivering advanced solutions for leak detection and package integrity testing. Our expertise lies in creating reliable instruments that help manufacturers ensure their products are protected, consistent, and safe.

At MSA, we dedicate ourselves to protecting lives by delivering products and technologies that safeguard workers in critical environments. We design and manufacture advanced safety solutions that give our customers confidence and peace of mind.

At UE Systems, we dedicate ourselves to advancing ultrasonic technology that helps our customers improve reliability, efficiency, and safety in their operations. We specialize in the development of leak detectors that allow facilities to identify and resolve issues in compressed air, gas, and vacuum systems before they become costly problems.

More Leak Tester Manufacturers

Unlike leak detectors, leak testers generally do not monitor systems; instead they are used as a diagnostic tool when a given system is running at less than optimal levels. Appliances using refrigerants and methane gases should be tested at the first sign of decreased productivity because the release of these materials can be hazardous to health.

Leaking gases can also lead to loss of money and eventually to appliance failure. Depending on the type of leak, the substance can also hurt the environment. As many methods and techniques for leak testing are available, the specifications of the mechanism to be tested should be considered. Pressure decay, mass flow, helium accumulation, vacuum decay and colorimetric development are some of the many testers available.

Some of these systems recognize changes in pressure or flow, while others use chemicals to produce visible reactions at the site of a leak.

The most simple leak tester, the bubble test, involves submerging a pressurized test subject in water or coating it in a soapy substance, at which time bubbles emerge from the site of the leak. Although the bubble test is effective and inexpensive, it is not applicable to sensitive equipment. Leak testers should be carefully chosen for more sensitive equipment and situations.

Also, testers do not identify the substance that is leaked and so are often used in conjunction with liquid or gas analyzers. These products in the leak detection line are meant for fairly specific scenarios, although leak detection are more generalized. That is why using leak detectors and leak testers together, produces a well-rounded solution.

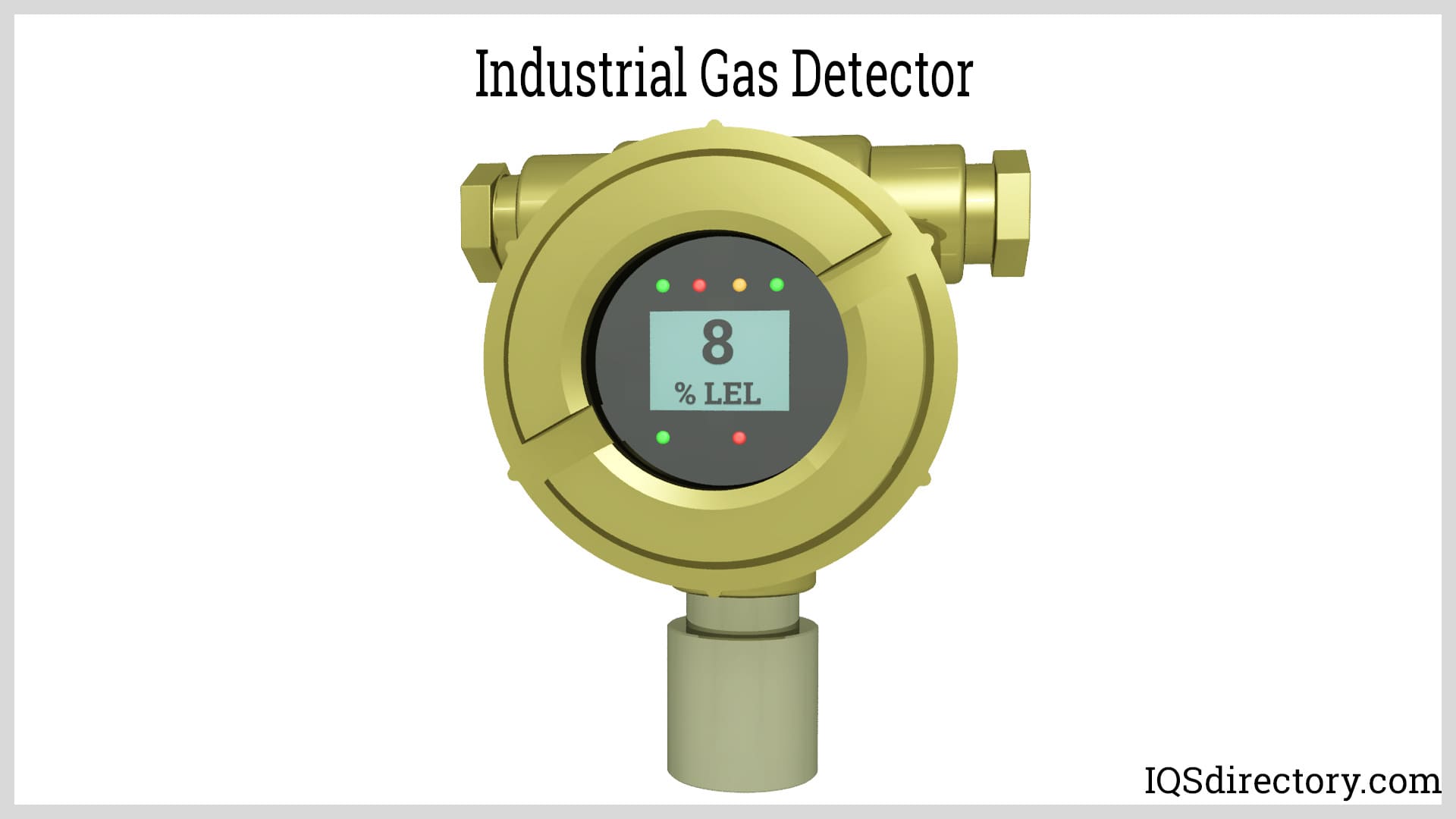

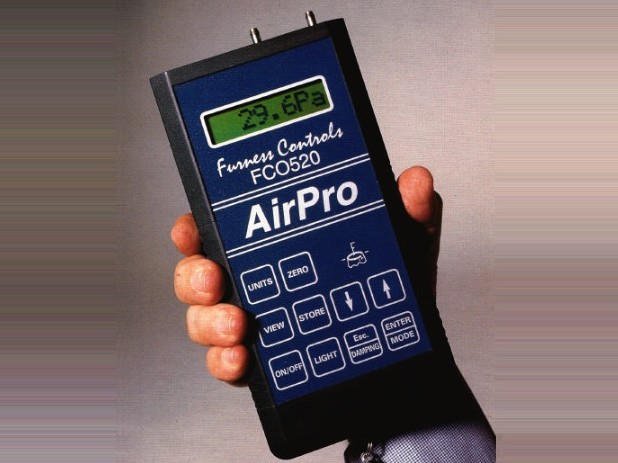

A variety of methods exist to detect a leak. Gas detectors use a tracer gas to measure the leak based on its ion charge response to the helium or hydrogen they put into the air. Ultrasonic detectors measure the sound waves emitted by gas leaks to locate and identify a leak. Often these detectors are hand held, since leaks usually originate in complex pipe systems that are difficult to maneuver.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services