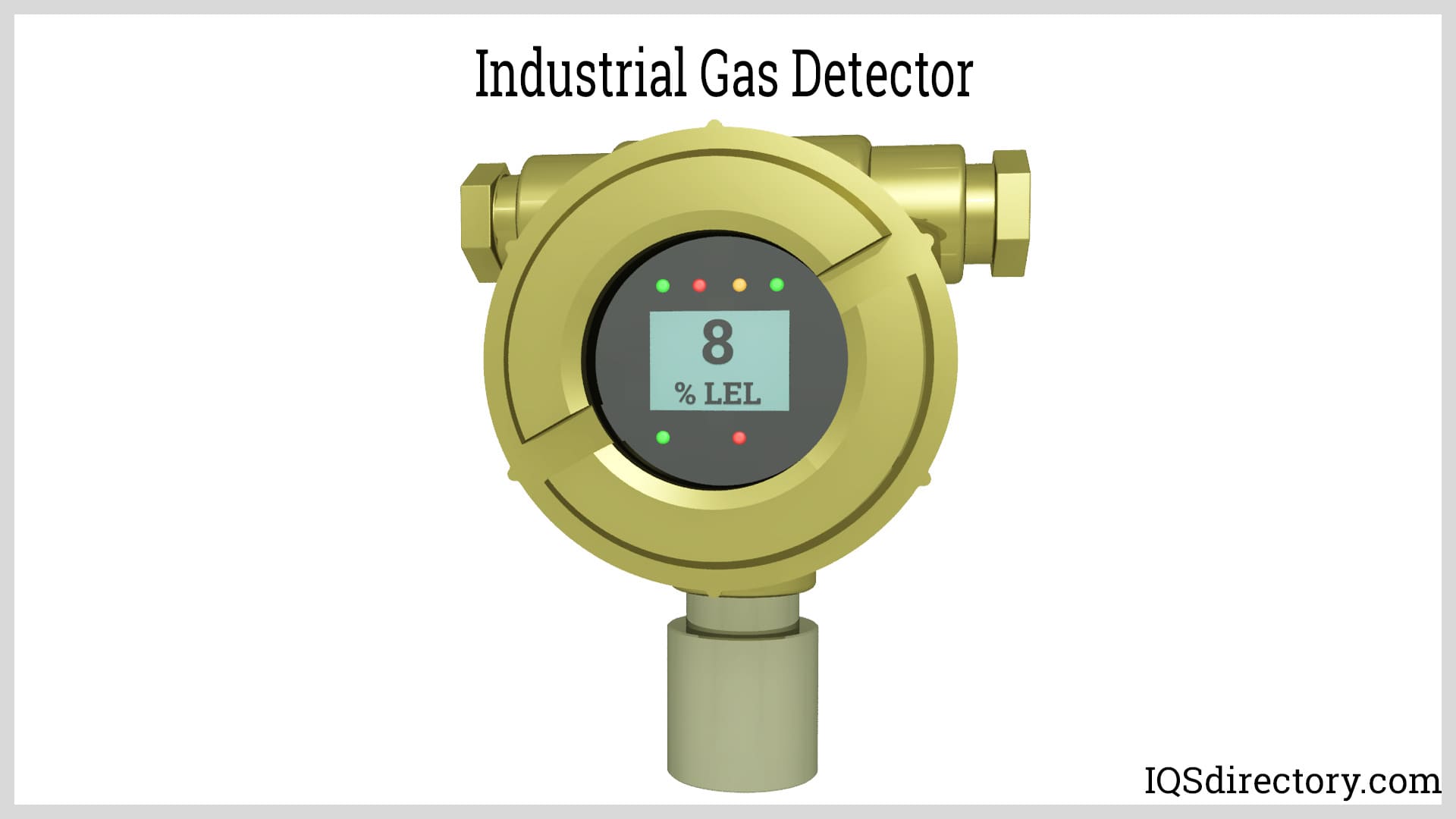

A gas detector is a tool that frequently checks for the presence of gasses in space as a safety measure. Operators near the leak may hear an alarm from a gas detector, giving them a chance to flee. This apparatus is crucial since many gasses can potentially be toxic to organic life, including people and animals. They frequently gauge gas concentrations and identify explosive or dangerous gasses. Oxygen depletion and poisonous, explosive, and combustible gasses can all be monitored with gas detectors. As a safety system component, gas detectors measure or watch for the loss of oxygen, poisonous gasses, and flammable gasses in a given space. Read More…

We are AMETEK MOCON, and we are dedicated to delivering advanced solutions for leak detection and package integrity testing. Our expertise lies in creating reliable instruments that help manufacturers ensure their products are protected, consistent, and safe.

At MSA, we dedicate ourselves to protecting lives by delivering products and technologies that safeguard workers in critical environments. We design and manufacture advanced safety solutions that give our customers confidence and peace of mind.

At UE Systems, we dedicate ourselves to advancing ultrasonic technology that helps our customers improve reliability, efficiency, and safety in their operations. We specialize in the development of leak detectors that allow facilities to identify and resolve issues in compressed air, gas, and vacuum systems before they become costly problems.

More Gas Detector Manufacturers

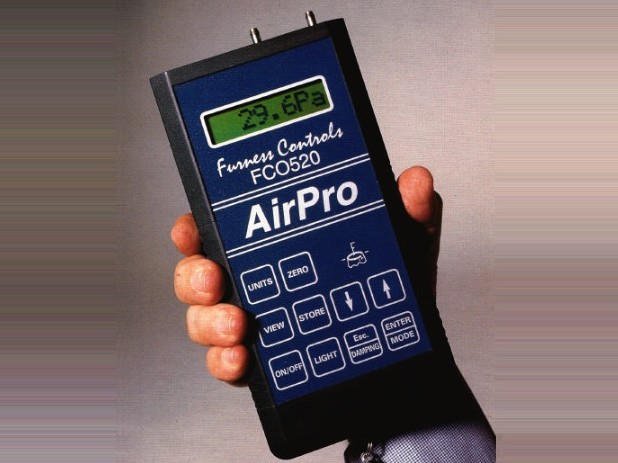

The method of locating potentially dangerous gas leaks using sensors is known as gas leak detection. Additionally, a thermal camera can be used for visual identification. When a harmful chemical is present, these sensors often use an audible warning to warn people. Painting, fumigation, fuel filling, construction, excavation of contaminated soils, landfill operations, entering restricted spaces, and other activities can also expose workers to harmful fumes.

Common sensors include metal-oxide-semiconductor (MOS) sensors, infrared point sensors, photoionization detectors, flammable gas sensors, ultrasonic sensors, and photoionization detectors. Infrared imaging sensors have been used more lately.

These sensors are all found in industrial facilities, refineries, pharmaceutical production facilities, fumigation facilities, paper pulp mills, aircraft and shipbuilding facilities, hazmat operations, waste-water treatment facilities, cars, indoor air quality monitoring facilities, and households. Gas sensors require more frequent calibration than many other types since they continually react with air and other gasses.

Types of Gas Detectors

There are many types of gas detectors available these days.The four main types of gas detector technologies utilized to detect harmful gasses are listed below:

- Photoionization Sensors

- Electrochemical

- Catalytic Bead

- Infrared

Photoionization Gas Detectors

A photoionization gas detector ionizes gasses into positive and negative ions that are simple for a detector to detect using an ultraviolet light source. When a molecule takes in a gas's light energy, ionization happens. The charge of ionized gasses is detected or measured by photoionization, which depends on the amount of volatile organic compounds (VOCs) in the atmosphere.

Electrochemical Gas Sensors

Electrochemical gas detectors determine the concentration of a particular gas by oxidizing or reducing the gas to an electrode and creating a positive or negative current flow. Electrochemical gas sensors are commonly used to monitor the concentration of a target gas inside an external circuit. The most widely used and well-understood combustible gas technologies are electrochemical and catalytic, although numerous other types of gas detectors exist.

Catalytic Bead Sensors

When concentrations are between the lower explosion limit (LEL) and the upper explosion limit (UEL), catalytic gas detectors are commonly employed to measure flammable gasses that pose an explosion threat. Catalytic gas detectors work on the premise that heat is produced when a gas oxidizes, and the sensor will convert this change in temperature using a Wheatstone bridge-style circuit.

The catalytic sensor has two beads: one is coated to suppress oxidation, and the other contains a unique catalyst that stimulates oxidation. The platinum coil's resistance increases as current flows through it until it reaches oxidation temperature (500° Celsius), which causes an imbalance in the bridge.

Infrared Gas Sensors

Infrared sensors are utilized as an alternative to combustible gas readings when no oxygen is available or when excessive carbon dioxide concentrations are observed. The change in the intensity of the absorbed light is measured by the light intensity at a reference wavelength using the principle of light absorption. The infrared sensor calculates the variation in light absorption and reports the gas concentration.

Applications of Gas Detectors

Transportation Applications

The transportation sector requires gas detectors to measure CO2 and O2 levels in cargo.

Agricultural Applications

Gas detectors are built to measure carbon dioxide to optimize the conditions needed to enhance plant yields.

Medical and Life Science Applications

The usage of gas sensing technology is widely used in the medical field and life science industries. High-quality gas sensors provide precise, dependable, and consistent solutions that may be integrated into various applications, including capnography, respiration, neurology, and incubation.

Homes

Gas detectors measure indoor air quality by detecting the available gas concentration.

Advantages of Gas Detectors

- They are quick and accurate in detecting hazardous and flammable gas hazards.

- They feature compact, lightweight monitors with audible, visible, and vibrating alarms for clip-on or belt use.

- They are simple to use, having a single button and pre-set alarm volumes.

- They are simple to maintain.

- Built-in data and event-logging capabilities lessen the workload for plant controllers.

Disadvantages of Gas Detectors

- They are expensive to buy.

- They require calibration now and then.

Choosing the Correct Gas Detector Supplier

To ensure you have the most positive outcome when purchasing gas detectors from a gas detector supplier, it is important to compare several companies using our directory of gas detector suppliers. Each gas detector supplier has a business profile page highlighting their experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each gas detector business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple gas detector companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services