A mass spectrometer leak detector (MSLD), commonly referred to as a helium leak detector, locates leaks in a container and evaluates their magnitude. objects suspected of leaking are linked to the leak detector, and then exposed to the tracer gas, helium. Read More…

We are AMETEK MOCON, and we are dedicated to delivering advanced solutions for leak detection and package integrity testing. Our expertise lies in creating reliable instruments that help manufacturers ensure their products are protected, consistent, and safe.

At MSA, we dedicate ourselves to protecting lives by delivering products and technologies that safeguard workers in critical environments. We design and manufacture advanced safety solutions that give our customers confidence and peace of mind.

At UE Systems, we dedicate ourselves to advancing ultrasonic technology that helps our customers improve reliability, efficiency, and safety in their operations. We specialize in the development of leak detectors that allow facilities to identify and resolve issues in compressed air, gas, and vacuum systems before they become costly problems.

More Helium Leak Detector Manufacturers

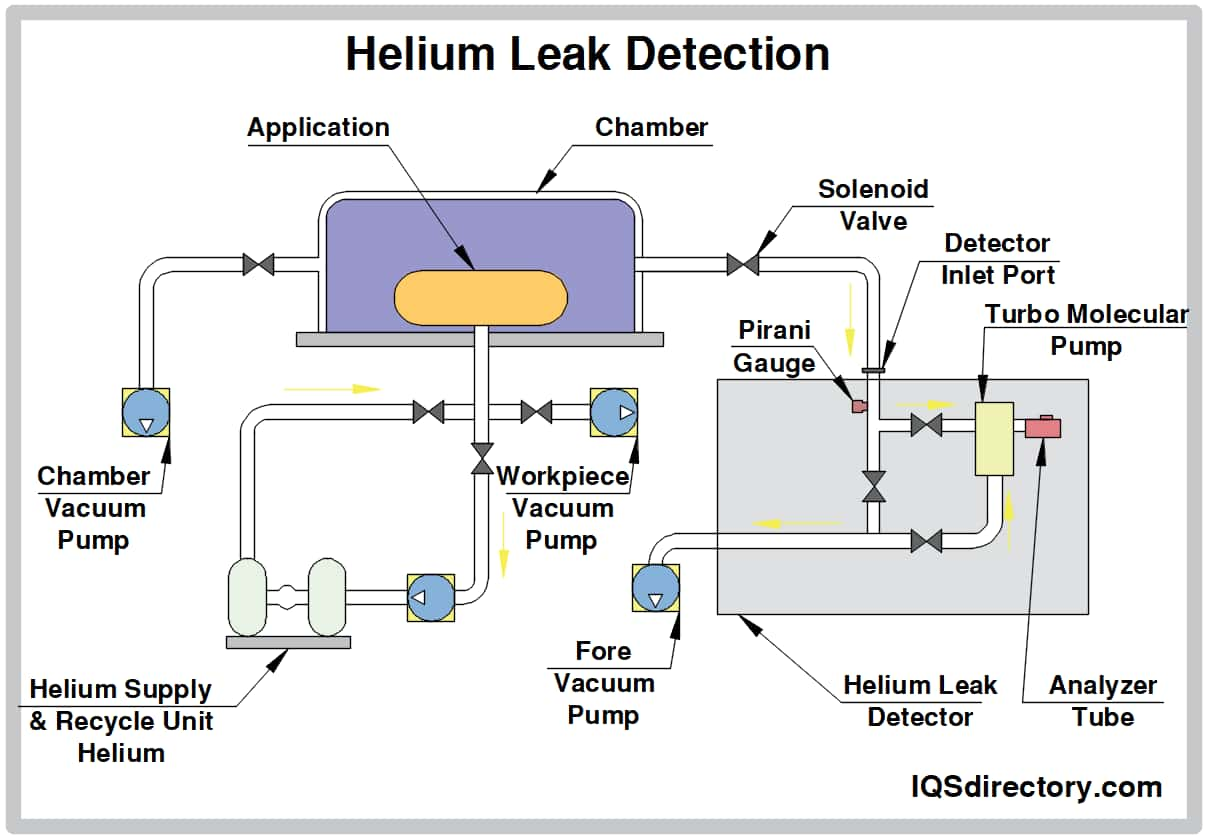

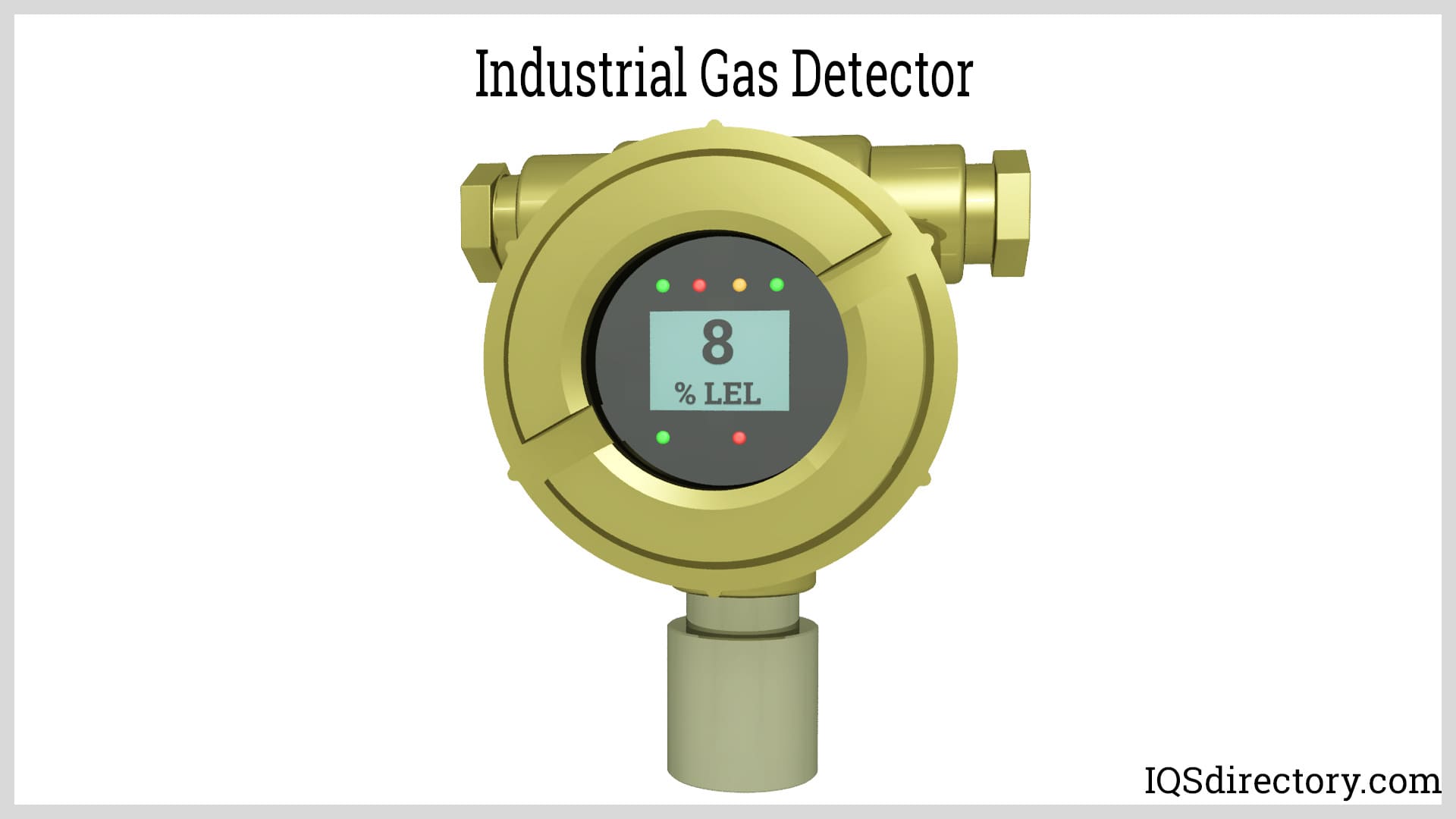

The system captures the helium leaking through the object, measures the helium, and displays results ona a meter. Helium leak detectors are comprised of:

- A spectrometer that measures helium mass

- A vacuum system to keep the spectrometer's pressure constant

- A mechanical pump to expel the test-piece material

- Valves that permit the various detection stages: egress, testing, and venting

- A signal monitor that uses readout instruments and an amplifier

- Energy sources and controls

- Fixtures that secure the test component to the detector

Helium Leak Detection Process

The best option for leak detection and leak-tightness testing in a vacuum is helium leak detectors. Helium, a test gas that can be used to find tiny leaks, is a harmless, small, and light molecule. Detecting helium leaks is a highly precise, quantifiable process. Automatic leak detection systems are operator-free and work quickly. Gas leak detection methods supply more data than conventional bubble testing or pressure drop techniques. The extra data helps to enhance various manufacturing procedures.

Helium Leak Detection Methods

The two primary techniques for helium leak testing are vacuum testing and pressure testing (inside-out). When choosing which technique, consider the natural environment around the object you are testing. It is crucial to maintain the same pressure levels during the test as those that will apply when the part is actually used. Vacuums should be present inside the chamber for testing vacuum systems. A compressed air cylinder should be put through a high pressure test.

In vacuum testing detects leaks by working from the outside in. This means the part you are testing is put inside of the detector. If a high volume of leakage is suspected, it may be wise to test the component with a separate pumping system. A spray probe applies helium to potential leaking areas.

Pressure testing involves using helium to pressurize the tested components. A sniffer probe attached to the leak detector scans the part being tested.

Applications of Helium Leak Detectors

Helium leak detectors can be used for quality control in assembly processes. Hermetic packages, valves, manifolding, seals, vacuum vessels and systems, and medical equipment are examples of parts often tested for helium.

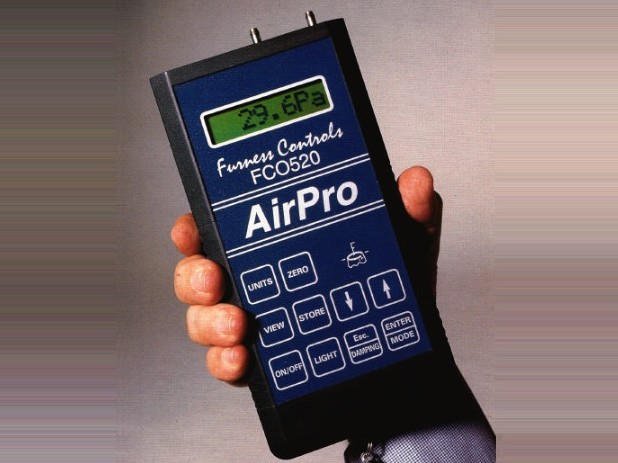

Helium leak detectors are also available as portable mechanisms, which is helpful given that leaks frequently occur in pipelines that are underground, in the ceiling, or in the walls and are difficult to access.

Helium leak detectors can be used in underground pipelines, steam turbine and condenser air leakage testing, chemical and plastics production. Industries like aircraft, automotive, industrial, hydrogen energy, medical, packaging, RAC/HVAC, utilities, and power frequently use helium leak detection.

Maintenance of Helium Vacuum Leak Detectors

Tools used in industrial processes that rely on vacuum or pressure systems must be put through testing to look for sporadic leaks. This may be done as a part of routine maintenance or in the event of a sudden breakdown. Vacuum systems include Vacuum pumps or tanks. Gas handling systems, liquid gas facilities, or underground tanks are typical examples of pressurized systems.

Conclusion

Helium gas is a user-friendly component for leak testing. helium is often the first choice for leak detection because it is simple and affordable to purchase.

Choosing the Proper Helium Leak Detector Manufacturer

To ensure you have the most beneficial outcome when purchasing helium leak detectors from a helium leak detector manufacturer, it is important to compare several companies using our directory of helium leak detector manufacturers. Each helium leak detector manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each helium leak detector business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple helium leak detector companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services