Leak detection is a technique used to find leaks in industrial systems. The detection techniques can be internal or exterior, depending on where the leak detection system is installed. Leaks often escape when a metal container begins to suffer from corrosion. Leak detection offers an alternate way to test for corrosion damage. Read More…

We are AMETEK MOCON, and we are dedicated to delivering advanced solutions for leak detection and package integrity testing. Our expertise lies in creating reliable instruments that help manufacturers ensure their products are protected, consistent, and safe.

At MSA, we dedicate ourselves to protecting lives by delivering products and technologies that safeguard workers in critical environments. We design and manufacture advanced safety solutions that give our customers confidence and peace of mind.

At UE Systems, we dedicate ourselves to advancing ultrasonic technology that helps our customers improve reliability, efficiency, and safety in their operations. We specialize in the development of leak detectors that allow facilities to identify and resolve issues in compressed air, gas, and vacuum systems before they become costly problems.

More Leak Detection Manufacturers

Comprehensive Guide to Leak Detection: Methods, Applications, and Choosing Providers

Effective leak detection is essential for industries ranging from utilities and manufacturing to food processing and HVAC systems. Whether you are seeking solutions for gas leak detection, water leak detection, or specialized industrial leak detection applications, understanding the technology, use cases, and benefits can help you safeguard assets, reduce costs, and comply with environmental regulations. This guide covers the types of leak detectors, their applications, benefits, and how to choose the right leak detection service provider.

What is Leak Detection?

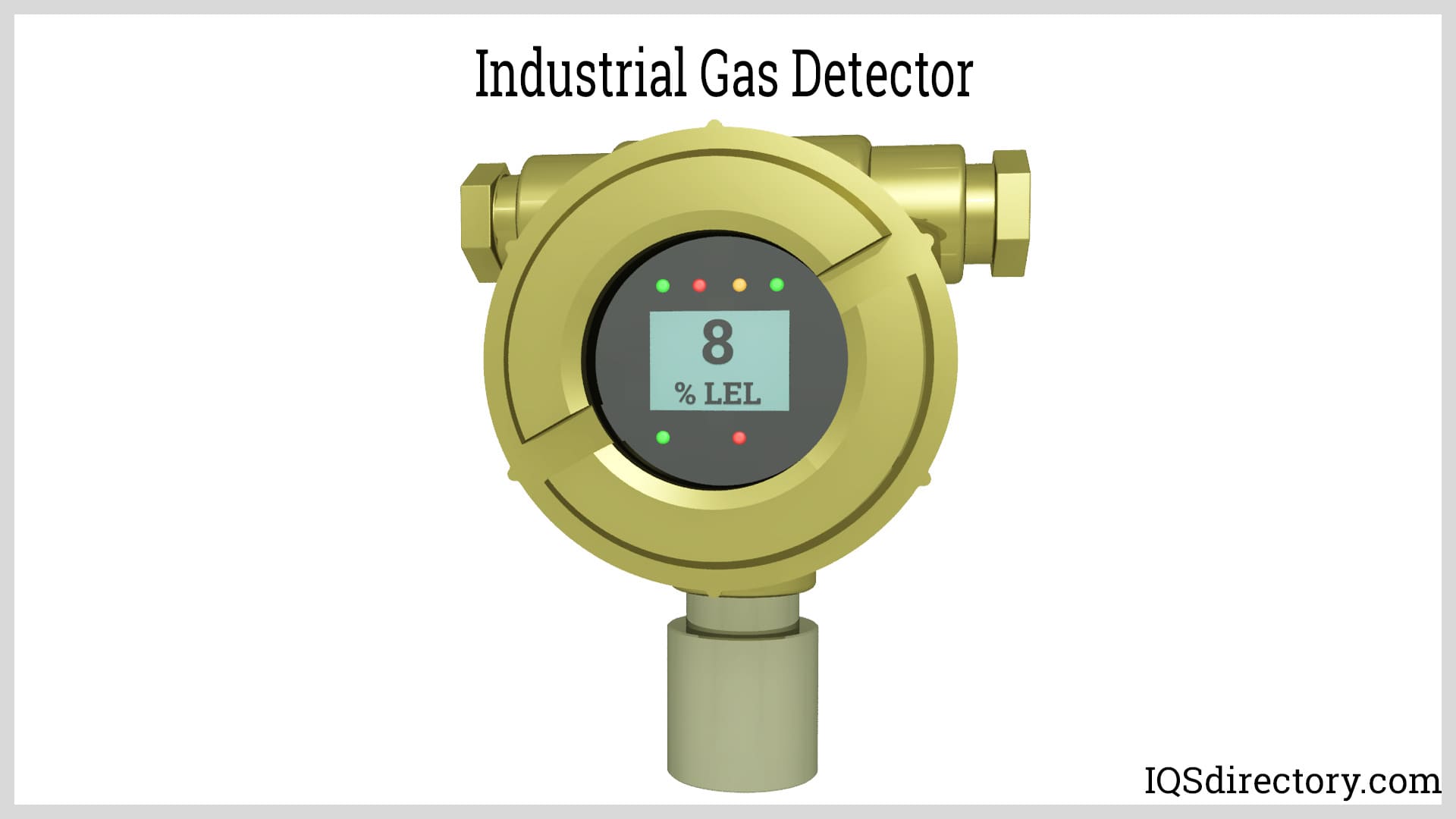

Leak detection refers to the process of identifying and locating unintentional discharges of liquids or gases from pipelines, containers, or industrial systems. Manual inspection tools and automated leak detection systems are used to monitor and alert operators to leaks, minimizing the risk of product loss, environmental harm, and equipment damage. Modern leak detection methods leverage advanced sensors, real-time monitoring, and data analytics to offer accurate leak location, size estimation, and severity assessment.

Are you wondering, “How does a leak detector work?” or “What type of leak detection system is best for my application?” Read on for detailed information about the most common leak detection technologies and their specific use cases.

Types of Leak Detectors and Leak Detection Methods

Choosing the right leak detection technology depends on the medium (liquid or gas), system pressure, environmental concerns, and operational requirements. Below are some of the most widely used leak detection devices and sensors—each with unique detection principles, benefits, and best-fit applications.

1. Acoustic Leak Detector

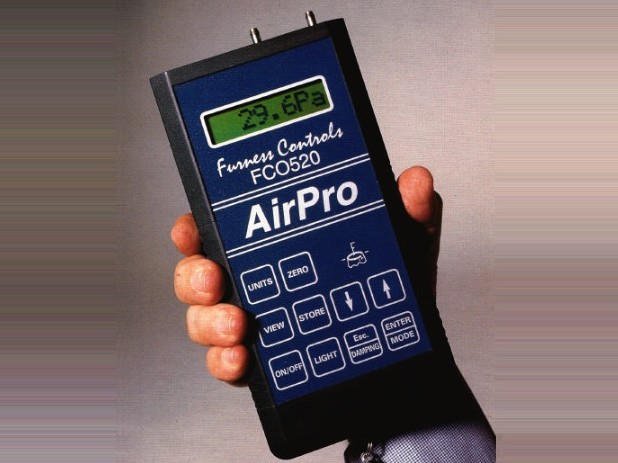

Acoustic leak detectors utilize highly sensitive transducers to record the sound waves produced by leaks in pressurized pipes or vessels. Leaks generate distinctive noises—such as hissing, whooshing, splashing, or thudding—depending on the material, leak size, and system pressure. These ultrasonic or sonic signals are analyzed by the detector, which pinpoints the leak’s location and notifies technicians or facility managers. Acoustic detection is ideal for pipeline leak detection, buried water mains, and pressurized gas systems where traditional visual inspection is impractical.

- Best for: Water leak detection in utilities, HVAC lines, and underground infrastructure

- Key benefit: Non-invasive, enables early leak localization

2. Flame Ionization Detector (FID)

A flame ionization detector is primarily used for the detection and quantification of organic gases and hydrocarbons. This technology relies on a hydrogen-air flame and an electrode system. As gas samples pass through the flame, organic compounds ionize and generate an electrical current proportional to the concentration of hydrocarbons present. FIDs are widely used in environmental monitoring, petrochemical plants, and safety inspections for detecting combustible gas leaks.

- Best for: Gas leak detection in oil & gas, refineries, and chemical industries

- Key benefit: Extremely sensitive to a wide range of volatile organic compounds (VOCs)

3. Fluorescent Leak Detection

Fluorescent leak detection is a rapid, non-intrusive method for locating leaks in closed-loop systems, such as hydraulic circuits, coolant loops, and refrigeration systems. A fluorescent dye compatible with the system’s working fluid is introduced and circulated. When exposed to ultraviolet (UV) or violet light, the dye glows brightly at the leak site, making even the smallest leaks instantly visible. This method is particularly valuable in automotive, aerospace, and industrial maintenance applications.

- Best for: Automotive leak detection, refrigeration, HVAC, and hydraulic systems

- Key benefit: Fast, accurate, and safe for most materials

4. Infrared Open Path Gas Leak Detection

Infrared (IR) open path gas detectors utilize the principle of infrared absorption to detect gas leaks over extended distances. The system consists of a light source and an IR detector. As infrared radiation passes through the air, gas molecules in the path absorb specific wavelengths, and the detector measures the reduction in intensity. By comparing active and reference absorption wavelengths, the system calculates gas concentration and issues an alarm if thresholds are exceeded. IR open path detectors are highly effective for perimeter monitoring, outdoor storage areas, and industrial facilities handling hazardous gases.

- Best for: Perimeter gas leak detection in petrochemical plants, tank farms, and outdoor process zones

- Key benefit: Wide coverage area, rapid response, and minimal maintenance

5. High Voltage Leak Detection

High voltage leak detection methods are used for quality control and defect detection in manufactured components—especially those requiring impermeability, such as packaging, coatings, and electrical insulators. The test item is placed between two electrodes; one is grounded and the other is supplied with high voltage. If a dielectric flaw or pinhole is present, current will flow, indicating a leak. This technique ensures product integrity in high-speed production environments, including the pharmaceutical and food packaging sectors.

- Best for: Pinhole and dielectric flaw detection in packaging, electronics, and medical device manufacturing

- Key benefit: High throughput, objective pass/fail results

6. Electronic and Digital Leak Detectors

Modern electronic leak detectors utilize advanced sensors—such as semiconductor, electrochemical, or photoionization detectors—to identify the presence of gases like refrigerants, ammonia, or natural gas. Many digital leak detectors feature real-time readouts, data logging, and wireless connectivity, making them ideal for predictive maintenance, smart building monitoring, and compliance with safety regulations.

- Best for: HVAC leak detection, commercial refrigeration, and building automation

- Key benefit: Automated alerts, data analytics, and integration with IoT platforms

Industrial and Commercial Applications for Leak Detectors

Leak detection systems are essential in a wide variety of industries. Understanding your sector’s specific requirements will help you choose the optimal technology and provider.

- Hydraulics: Internal leaks in hydraulic systems are difficult to spot visually. Leak detectors enable early fault detection, preventing equipment failure and costly downtime.

- Food Packaging: Leak detection ensures that food packaging is hermetically sealed, preventing spoilage, contamination, and regulatory violations.

- Air Conditioning and Refrigeration: Detecting leaks in air conditioning and refrigeration systems prevents refrigerant loss, reduces environmental impact, and extends compressor life.

- Oil & Gas Pipelines: Leak detection technologies safeguard against hazardous leaks in pipelines, storage tanks, and processing plants, ensuring safety and regulatory compliance.

- Water Distribution Networks: Proactive leak detection reduces non-revenue water loss, supports asset management, and enhances service reliability for utilities.

- Pharmaceuticals and Medical Devices: High voltage and tracer gas leak testing ensure the sterility and safety of medical packaging and devices.

- Automotive Manufacturing: Leak testing for cooling systems, fuel lines, and air conditioning components improves product quality and customer satisfaction.

Benefits of Leak Detection Systems

Investing in an advanced leak detection system offers numerous advantages for businesses, municipalities, and facility managers. Here are the most important benefits:

- Loss Prevention: Leak detection systems help avoid product loss—whether it’s water, chemicals, fuel, or gas—directly impacting profitability. Early leak identification and repair reduce waste and unplanned downtime.

- Environmental Protection: Rapid detection and containment of leaks prevent soil and water contamination, reduce hazardous emissions, and support compliance with environmental regulations.

- Labor Reduction and Efficiency: Automated leak detectors eliminate the need for manual inspection and excavation, allowing maintenance teams to focus on critical repairs rather than time-consuming leak searches.

- Operational Continuity: Leak detection devices are designed to operate in the background, providing continuous protection without disrupting daily operations. Strategically placed sensors maximize data collection and risk mitigation.

- Regulatory Compliance: Many industries are subject to strict regulations regarding leak detection and reporting. Implementing compliant systems supports audits, avoids fines, and demonstrates commitment to safety.

- Sustainability: Minimizing leaks aligns with sustainability goals by conserving resources, lowering energy use, and reducing greenhouse gas emissions.

- Asset Protection: By identifying leaks before they escalate, leak detection safeguards infrastructure, extends equipment life, and maintains brand reputation.

Common Leak Detection Use Cases

- Residential Leak Detection: Homeowners use water leak detectors and smart sensors to protect against burst pipes, foundation leaks, and appliance failures.

- Commercial Buildings: Facility managers deploy integrated leak monitoring systems to minimize property damage and business interruption.

- Municipal Water Utilities: Cities leverage acoustic and pressure-based systems to reduce water loss and improve infrastructure planning.

- Industrial Manufacturing: Automated leak detection enables predictive maintenance, reducing unscheduled shutdowns and improving overall equipment effectiveness (OEE).

- Hazardous Environments: Explosion-proof gas leak detectors safeguard personnel and assets in chemical plants, refineries, and confined spaces.

- Aerospace and Defense: Leak testing ensures the integrity of critical fuel, hydraulic, and environmental control systems.

How to Select the Best Leak Detection Company

Choosing a reputable leak detection company or service provider is crucial for ensuring effective leak monitoring, prompt repair, and regulatory compliance. Here are key decision factors to consider:

- Industry Experience: Does the company have proven expertise in your sector—such as water utilities, oil & gas, manufacturing, or commercial buildings?

- Technology Portfolio: Do they offer a full range of leak detection solutions, from acoustic and infrared sensors to electronic and digital systems?

- Service Coverage: Can they provide both on-site leak detection services and remote monitoring solutions?

- Certifications and Compliance: Are their systems certified for use in hazardous or regulated environments?

- Customer Support: Do they offer 24/7 support, maintenance contracts, and rapid response for emergency leak situations?

- References and Reviews: What do other customers say about their performance, reliability, and value?

- Cost and ROI: Does the provider deliver long-term value and return on investment through reduced losses, lower operating costs, and improved compliance?

To ensure the best outcome when selecting a leak detection partner, compare several businesses using our directory of leak detection companies. Each company profile highlights service areas, technologies, and industry focus. Use the contact form to request more information or a customized quote. For side-by-side comparisons, our website previewer lets you quickly assess capabilities and specialties. Ready to request multiple quotes? Use our convenient RFQ form to connect with several leak detection providers in just minutes.

Frequently Asked Questions About Leak Detection

- What is the most accurate leak detection method for pipelines?

For pipelines, a combination of acoustic monitoring, pressure-based sensors, and infrared leak detection offers the highest accuracy for both liquid and gas pipelines. The choice depends on pipe material, fluid type, and environmental conditions. - How do I detect water leaks in my home or business?

Water leaks can be detected using electronic water leak detectors, smart shutoff valves, and acoustic sensors. Many devices offer smartphone alerts for real-time monitoring and rapid response. - What regulations apply to leak detection systems?

Regulations vary by industry and jurisdiction. Common standards include EPA requirements for underground storage tanks, ASME and ASTM standards for industrial systems, and local building codes for commercial properties. - Can leak detection systems be integrated with building management systems (BMS)?

Yes, modern leak detectors often feature connectivity options—such as BACnet, Modbus, or wireless protocols—for seamless integration with building automation and facility management platforms. - What is the ROI of investing in leak detection?

The return on investment (ROI) comes from reduced product loss, lower repair costs, improved regulatory compliance, and enhanced asset protection. Most organizations recoup their investment within 1–3 years. - What are the signs of a hidden leak?

Common signs include unexplained increases in utility bills, damp spots, mold growth, musty odors, and reduced system pressure. Early detection is key to minimizing damage.

Conclusion: Protect Your Assets with Advanced Leak Detection Systems

Leak detection is no longer a luxury—it's a necessity for protecting people, property, and the environment. With the right leak detection solution, you can prevent costly losses, ensure regulatory compliance, and support sustainability goals. Whether you need gas leak detectors for hazardous environments, water leak detection systems for utilities, or leak detection services for commercial or residential properties, our directory connects you with top-rated providers and the latest technologies.

Still have questions? Get in touch with our experts or explore our company directory to take the next step in safeguarding your assets with industry-leading leak detection solutions.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services