This particular type of detector is used in a wide variety of industries to test hermetic seals, refrigeration, scientific and medical instrumentation, aerospace technologies, automotive and medical systems. Read More…

We are AMETEK MOCON, and we are dedicated to delivering advanced solutions for leak detection and package integrity testing. Our expertise lies in creating reliable instruments that help manufacturers ensure their products are protected, consistent, and safe.

At MSA, we dedicate ourselves to protecting lives by delivering products and technologies that safeguard workers in critical environments. We design and manufacture advanced safety solutions that give our customers confidence and peace of mind.

At UE Systems, we dedicate ourselves to advancing ultrasonic technology that helps our customers improve reliability, efficiency, and safety in their operations. We specialize in the development of leak detectors that allow facilities to identify and resolve issues in compressed air, gas, and vacuum systems before they become costly problems.

More Vacuum Leak Detector Manufacturers

Vacuum leak detectors have become integral to the family of leak detector tools because they are a reliable, economic and not easily biased option for leak detection. A style of leak tester, it is able to locate where a leak is but not what the substance is called that is leaking. Like all other leak detecting mechanisms, it works as one part of a system with multiple elements.

That is why a leak tester, which is able to identify the gas or liquid in the atmosphere, is a good complimentary tool. The vacuum detector can be used as a way to ensure the quality of the pipes as well as being pulled out when there is a drop in productivity and a leak is for sure. As the uses of this particular detector vary, so do the types offered.

Popular vacuum leak detectors include the turbo-molecular, back scrolling, rotary and dry running options, which offer many different features such as degree of tightness, pumping speed range and resistance to corrosion.

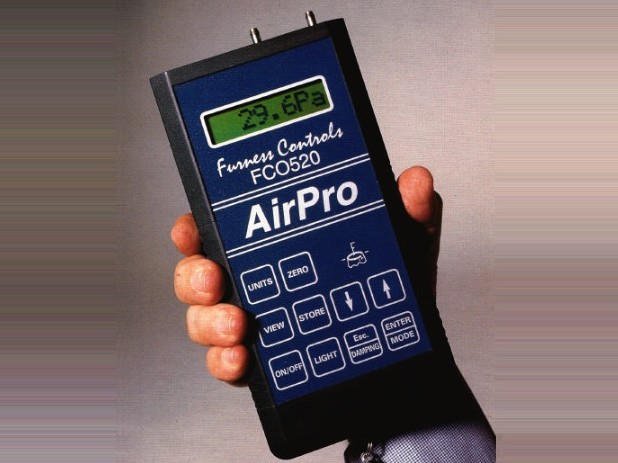

Though the pumps, valves, gauges and readouts vary between types of detectors, the basic function is the same. The vacuum leak detector is applied to a closed system, producing a vacuum in the tested tube. Compressed air, known as a tracer, is pumped into the system and the pressure is monitored.

A falling reading on the gauge indicates a leak, while the rate of the fall shows the severity of the leak. Though others may be used, helium is the most popular tracer gas as it is cheap, non-hazardous and nondestructive. Because the presence of helium in the atmosphere is low, it also enables testing with little concern for background interference when searching for the location of a leak.

Vacuum leak detectors were once too large and difficult to maneuver, but as technologies improve portable devices are widely available and affordable.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services